S3 Gearbox Removal

Discussion

Well, the time came for me to remove the gearbox to sort out the oil leak that has been staining the block paving and giving me serious ear-ake from Jane for the past few months.

All in all, it was not too bad (not done one on a TVR before) and got to the dropping the box out bit. Got my nephew round for a lift out. Dissy cap off, N/S cam cover removed as per tipps from other guys (thanks). Engine tilted rearwards.

Would it come out. No chance. After one and a half hours, we gave up and left the box wedged in between the chassis.

Plan B was to go to bed and hope it had fell out over night! Alas, it was still wedged in the chassis and stuck firm where the gearbox mounting brackets are fitted.

No matter which way it was tilted or twisted it would not clear. To this end, I pushed the box rearwards as far as it would go. I managed to remove the clutch and flywheel in situ. This gave me enough room to get the box out. I looked like I had been self harming if you saw my forarms as it was a bit tight to say the least. Still, the box was out. Changed the rear main oil seal, spigot bearing (top tip Andy on the special removing tool), input and output seals and gaskets (the input was pouring out) and clutch, although the new clutch had eight springs, not four, but apart from that, looked OK so decided to use it. 2.8 Capri clutch - Valeo.

Anyway, the reason for this post. I could not get the box back in, no matter how I tried. The box would not go past the mounting point brackets. I had to get the grinder on the 2 webs adjacent to the mounting brackets. I removed about 5mm deep and 15mm long on both sides and it went in. I would guess that the chassis are not all the same (hand made I would assume) and if you have a good un, happy days. If you have one that is a bit tight on tolerances, it is not so easy. Just my experience and I am sure others have done this job easily, but be warned. It may not be as easy as first thought? Gave up now, but the box is in and clutch pedal feels OK, all be it about 5mm of free play at the pedal end. Need to finish it to make sure its OK. Fingers crossed!

I removed about 5mm deep and 15mm long on both sides and it went in. I would guess that the chassis are not all the same (hand made I would assume) and if you have a good un, happy days. If you have one that is a bit tight on tolerances, it is not so easy. Just my experience and I am sure others have done this job easily, but be warned. It may not be as easy as first thought? Gave up now, but the box is in and clutch pedal feels OK, all be it about 5mm of free play at the pedal end. Need to finish it to make sure its OK. Fingers crossed!

Stew.

All in all, it was not too bad (not done one on a TVR before) and got to the dropping the box out bit. Got my nephew round for a lift out. Dissy cap off, N/S cam cover removed as per tipps from other guys (thanks). Engine tilted rearwards.

Would it come out. No chance. After one and a half hours, we gave up and left the box wedged in between the chassis.

Plan B was to go to bed and hope it had fell out over night! Alas, it was still wedged in the chassis and stuck firm where the gearbox mounting brackets are fitted.

No matter which way it was tilted or twisted it would not clear. To this end, I pushed the box rearwards as far as it would go. I managed to remove the clutch and flywheel in situ. This gave me enough room to get the box out. I looked like I had been self harming if you saw my forarms as it was a bit tight to say the least. Still, the box was out. Changed the rear main oil seal, spigot bearing (top tip Andy on the special removing tool), input and output seals and gaskets (the input was pouring out) and clutch, although the new clutch had eight springs, not four, but apart from that, looked OK so decided to use it. 2.8 Capri clutch - Valeo.

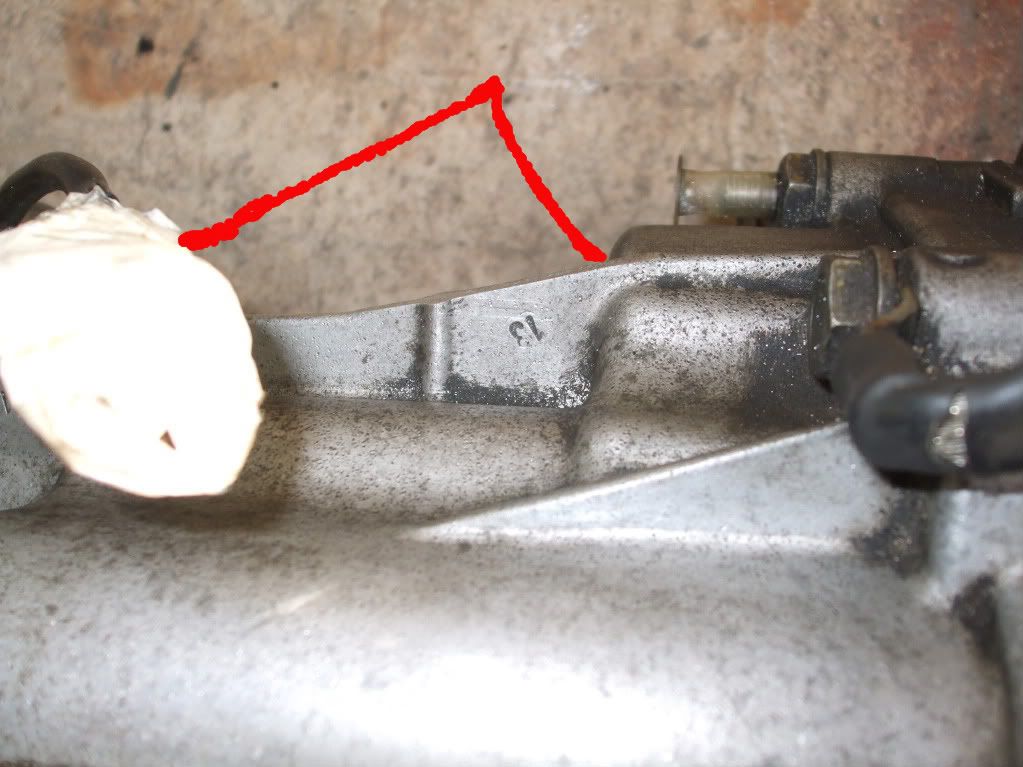

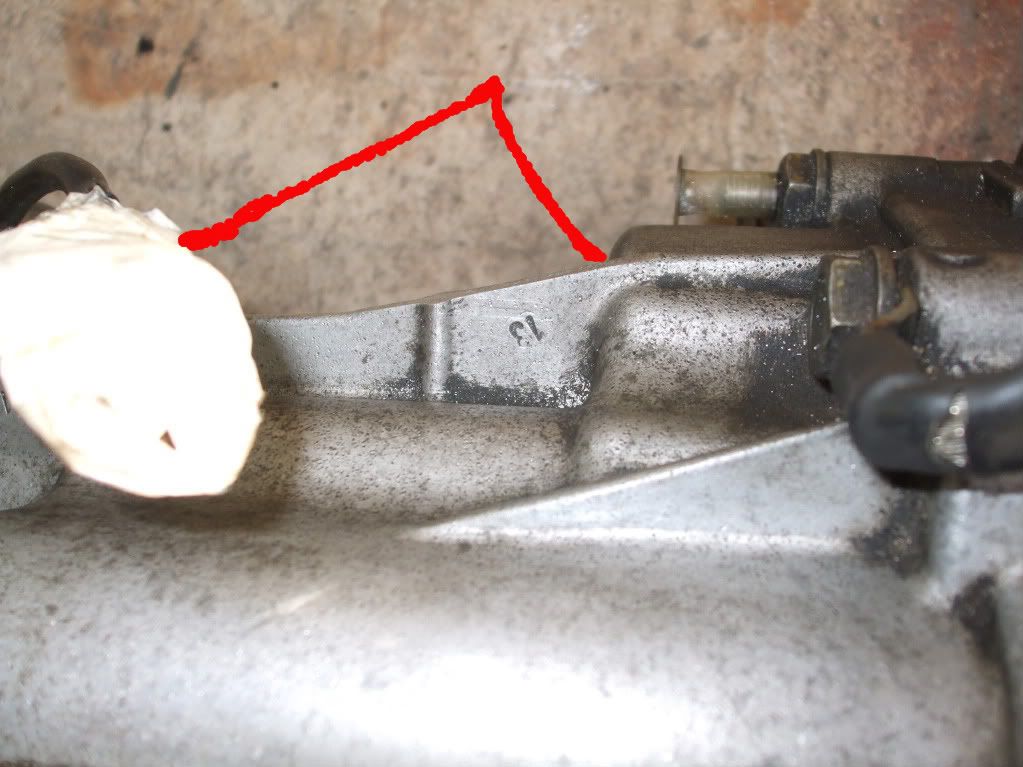

Anyway, the reason for this post. I could not get the box back in, no matter how I tried. The box would not go past the mounting point brackets. I had to get the grinder on the 2 webs adjacent to the mounting brackets.

I removed about 5mm deep and 15mm long on both sides and it went in. I would guess that the chassis are not all the same (hand made I would assume) and if you have a good un, happy days. If you have one that is a bit tight on tolerances, it is not so easy. Just my experience and I am sure others have done this job easily, but be warned. It may not be as easy as first thought? Gave up now, but the box is in and clutch pedal feels OK, all be it about 5mm of free play at the pedal end. Need to finish it to make sure its OK. Fingers crossed!

I removed about 5mm deep and 15mm long on both sides and it went in. I would guess that the chassis are not all the same (hand made I would assume) and if you have a good un, happy days. If you have one that is a bit tight on tolerances, it is not so easy. Just my experience and I am sure others have done this job easily, but be warned. It may not be as easy as first thought? Gave up now, but the box is in and clutch pedal feels OK, all be it about 5mm of free play at the pedal end. Need to finish it to make sure its OK. Fingers crossed!Stew.

Glad you finally got it done Stew.

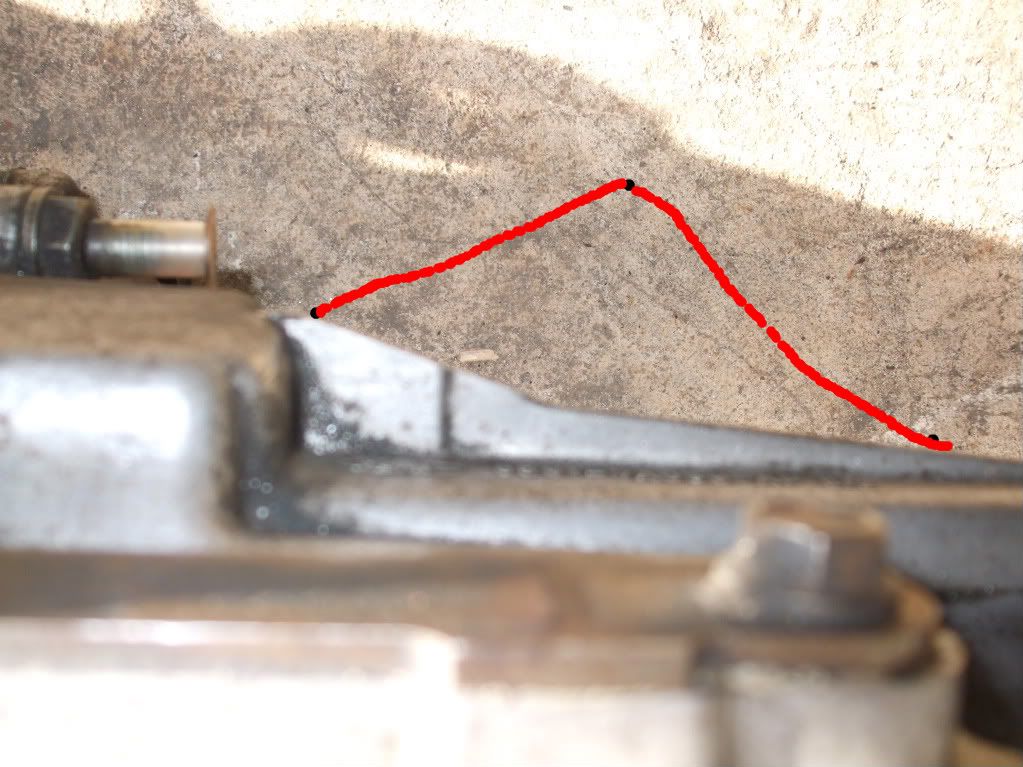

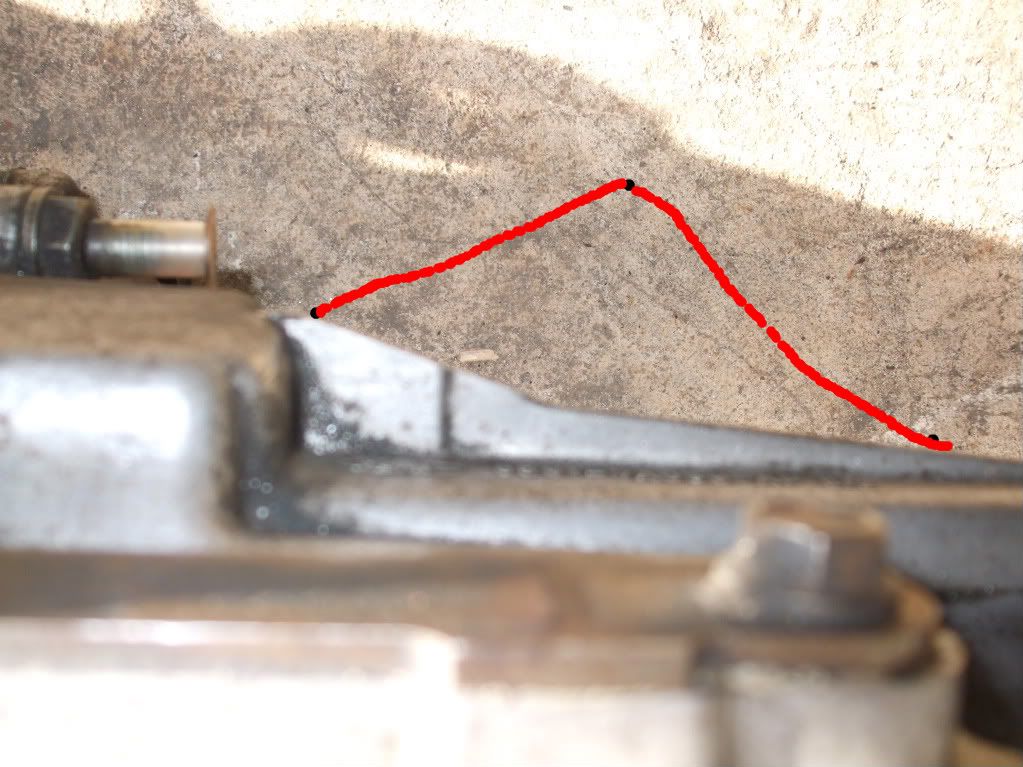

Had the same problem with the webs on the gearbox mine did come out eventually but I still could not tell you how a lot name calling as I recall etc.I looked like I had been a couple of rounds with Tyson cut lip and a nice scar to the face. I trimmed them away a bit in between the red lines to make refitting easier as well.

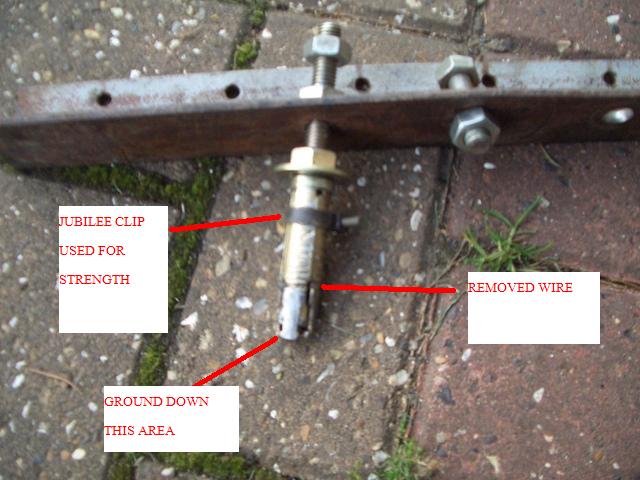

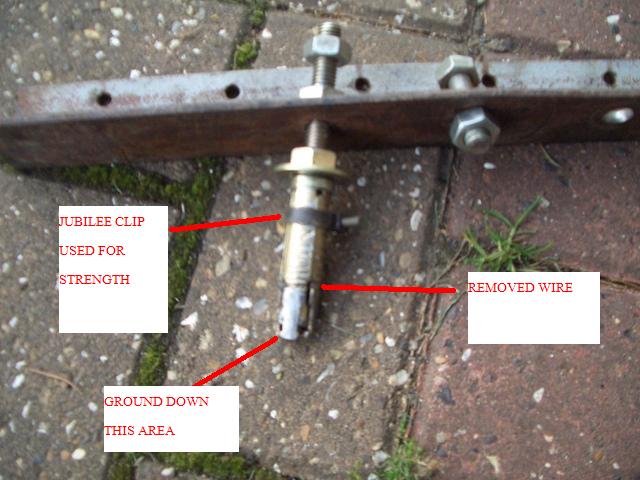

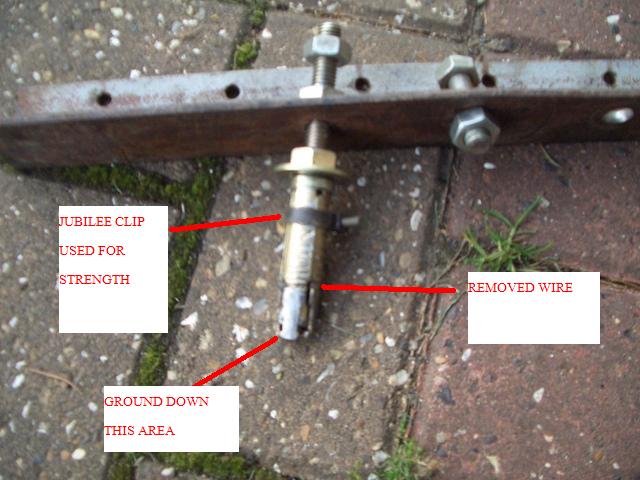

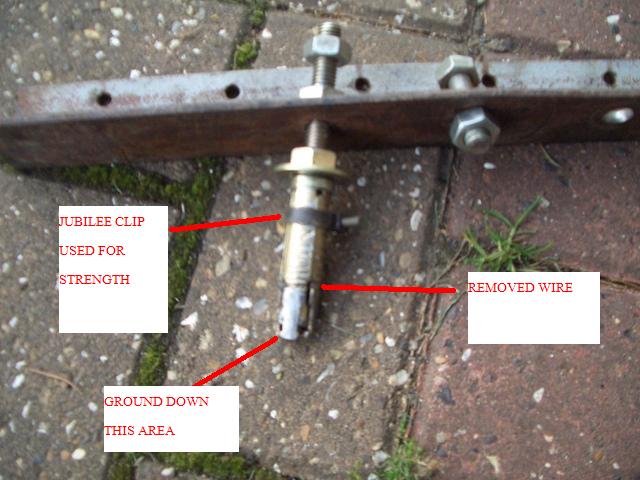

see pics hope this will help someone else(sorry about the dodgy redlines could not find the straight line thingy on photobucket)

and the bloody bracket

Cheers Andy

Had the same problem with the webs on the gearbox mine did come out eventually but I still could not tell you how a lot name calling as I recall etc.I looked like I had been a couple of rounds with Tyson cut lip and a nice scar to the face. I trimmed them away a bit in between the red lines to make refitting easier as well.

see pics hope this will help someone else(sorry about the dodgy redlines could not find the straight line thingy on photobucket)

and the bloody bracket

Cheers Andy

I got passed the chassis and the webs issue by twisting the box about 60 degrees one way then as it goes up slowly twisting it back to vertical and it went passed (just) I did think about your "web relieving option as that would make the whole job a lot easier, but was worried what it would do to strength of the box casing.

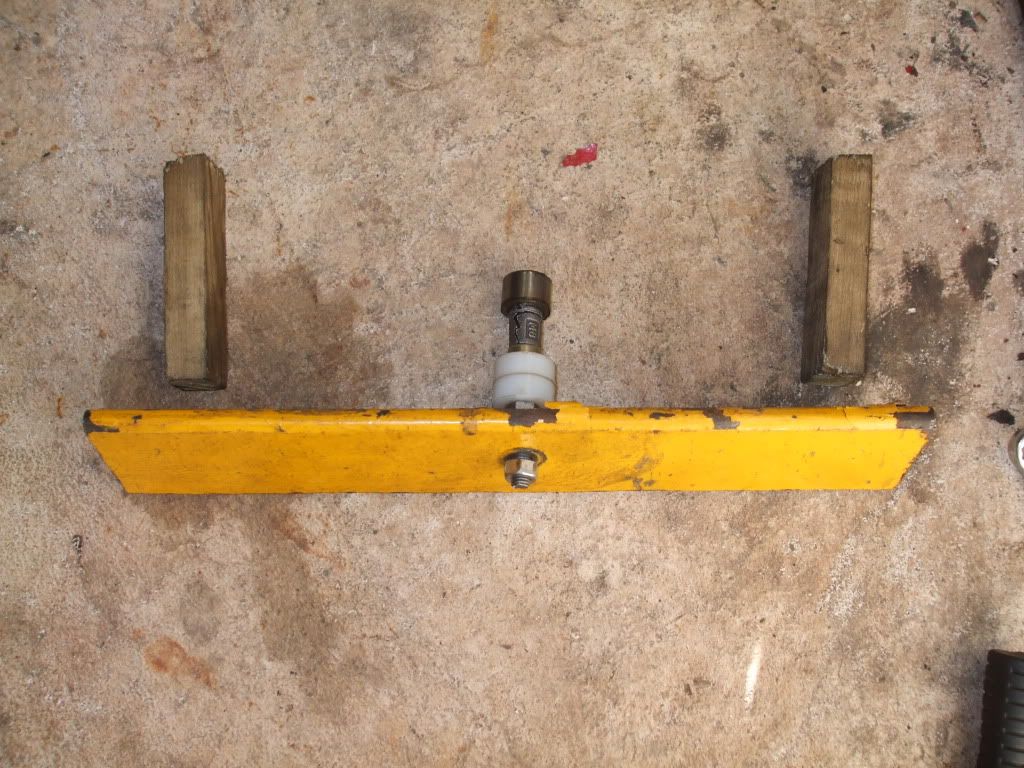

What was the "andy" tool for spigot bearing removal, was it this? If so glad to see my invention is helping others

Mark

What was the "andy" tool for spigot bearing removal, was it this? If so glad to see my invention is helping others

Mark

Edited by mep12345 on Tuesday 6th April 20:58

mep12345 said:

I got passed the chassis and the webs issue by twisting the box about 60 degrees one way then as it goes up slowly twisting it back to vertical and it went passed (just) I did think about your "web relieving option as that would make the whole job a lot easier, but was worried what it would do to strength of the box casing.

What was the "andy" tool for spigot bearing removal, was it this?

Mark

Thats the one Mark bloody good idea see below the Mark 11What was the "andy" tool for spigot bearing removal, was it this?

Mark

Saw it on your website saved me a lot of head scratching cheers

Edited by lou4010 on Tuesday 6th April 21:00

Tried the twisting approach but just could not get it past the mounting bracket and gave up after and hour and a half. Yes, had to modify the box in the same place as you Andy but did not read that bit in you gearbox post. Must have mist it - Bugger. I made a slight mod to Andy,s tool (if you pardon my French) idea, but basically the same principle. Worked a treat.

Gerald-TVR said:

Hi Stewart

been racking my brains about clutches. i just cant remember the details but there MIGHT be issues about the 2.8 clutch. Can I suggest you contact Adrian Venn Adrian@ Exactly TVR. I know he has the definative answers.

Norman

The issue is the rivets on the clutch plate butt against the flywheel and create a slipping clutch after a few thousand miles as the central section of the flywheel is slightly more flush (i.e. not recessed as far) than on the sierra/capri/granada etc. Adrian did post saying it could be machined out (and I think mine has been) to prevent the contact.been racking my brains about clutches. i just cant remember the details but there MIGHT be issues about the 2.8 clutch. Can I suggest you contact Adrian Venn Adrian@ Exactly TVR. I know he has the definative answers.

Norman

Mark

Thanks Chaps.

Yes, thats what Adrian told me about the flywheel as well. Mine had loads of room between the plate and flywheel inner surface. My new clutch plate was also slimmer than the old one having smaller springs but twice as many so do not think I have an issue. I also think that this was not the original clutch so work may have been done the the flywheel prviously.

Two chances it will be OK I guess.

Stew.

Yes, thats what Adrian told me about the flywheel as well. Mine had loads of room between the plate and flywheel inner surface. My new clutch plate was also slimmer than the old one having smaller springs but twice as many so do not think I have an issue. I also think that this was not the original clutch so work may have been done the the flywheel prviously.

Two chances it will be OK I guess.

Stew.

Just took the old motor out for a test drive. The new clutch, slave cylinder etc works a treat. Clutch pedal feels lighter and gear selection good. Gearbox now nice and dry.

Found a stack of other bits to do while up on stands, so brakes replaced front and rear, cam cover gaskets, thermostat, rear diff oil changed, etc. General stuff really but it all adds up.

The down side is, I still have a leak from the O/S rear above the oil filter, so I presume the next job will be the head gaskets. Going to live with a bit of cardboard under the car for a few weeks and enjoy driving it, until I get a bit more enthusiasm to start stripping any more bits off the old motor.

Happy days!!!

Stew.

Found a stack of other bits to do while up on stands, so brakes replaced front and rear, cam cover gaskets, thermostat, rear diff oil changed, etc. General stuff really but it all adds up.

The down side is, I still have a leak from the O/S rear above the oil filter, so I presume the next job will be the head gaskets. Going to live with a bit of cardboard under the car for a few weeks and enjoy driving it, until I get a bit more enthusiasm to start stripping any more bits off the old motor.

Happy days!!!

Stew.

Gassing Station | S Series | Top of Page | What's New | My Stuff